SPIRALE VISION allows you to control all your equipments. As standard supply you have :

- an extra wide touch screen (15")

- 3 use levels :

- PRODUCTION : simple, clear and functional

- STANDARD : a multi-purpose level

- LABORATORY : oriented towards advanced tests

- a monitoring alarm in Shock or ESS mode guaranteeing that your tests can be reproduced

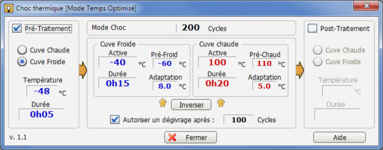

- programmable pre-treatment /post -treatment on SPIRALE VISION in order to condition the temperature, or even dry your samples at the start and / or end of the cycle.

- an automatic defrosting function : SPIRALE VISION optimises the cycle so that he defrosting can be correctl without disturbing the tested sample temperature.

The standard mode used to ver easily create programmes.

The optimised Time mode or "Guaranteed segment time" (Wait for mode) making it possible to guarantee a programme segment time whatever the quantity of samples loaded.

In Energy Saving mode only the cabinet containing the samples is running, thus reducing energy consumtion by 40 to 70%.